One of the recurring questions received by Gordian’s engineers revolves around the question of material impact on estimates. If prices on a type of material are surging, what are the tradeoffs of selecting another comparable option? Questions like these are becoming increasingly common as squeezed supply chain and wild material cost fluctuations have unsettled the construction market and made value engineering an imperative to make the most of project budgets.

For a practical example of the tradeoffs estimators and other considerations preconstruction professionals are making as they plan and design projects, look no further than the choice being made every day: copper versus aluminum wire.

From January 2021 to January 2022, the price of ½” copper tubing increased over 50%, while the average price of electric copper wire has grown over 120% in the same time frame. Many electrical engineers faced with these cost surges for copper materials are turning to aluminum as a substitute.

To help estimators and other construction professionals answer this question, we’ve turned to the industry expertise of Antonio D’Aulerio, Engineer on the Data Team, responsible for managing the electrical divisions for Gordian’s RSMeans Data. Antonio discusses the trade-offs for copper and aluminum materials and how to incorporate these decisions when using RSMeans Data Online.

Copper vs. Aluminum Wire

The main criteria for the use of aluminum cable vs copper cables are the cost savings. In buildings, aluminum and copper cables can be used interchangeably for power in low voltage installations. For communications and control, copper is more commonly used. In fact, nearly all electronic cables are made from copper.

The main difference between aluminum and copper cables is the current carrying capacity and resistance. Aluminum cable has a lower current carrying capacity (by about 40%) and greater resistance (requiring 50% larger cross-sectional area on average) than the equivalent copper conductor. As a rule of thumb, using aluminum conductors two American Wire Gage sizes larger than copper are typically sufficient for replacement. Aluminum will take more space to carry the same amperage as copper, meaning it will need a bigger raceway or enclosed channel designed for holding wires, cables or bus bars with additional functions.

The drawbacks for using aluminum:

- It’s less flexible and more labor intensive. Aluminum is more difficult to work with, so the cost of termination is higher.

- It needs a special compound at termination (or the lug must be a special Al-Cu type) to avoid galvanic corrosion. This can be a serious risk factor in damp conditions.

- For long runs, aluminum has more voltage drop so engineers may need to upsize the cable to compensate.

- Aluminum cable is prone to cracking and failure when subjected to vibration. This may be a greater consideration for industrial building projects where installed machinery produces high quantities of low and high frequency vibration.

Copper Versus Aluminum Wire: Using RSMeans Data Online to Estimate the Difference

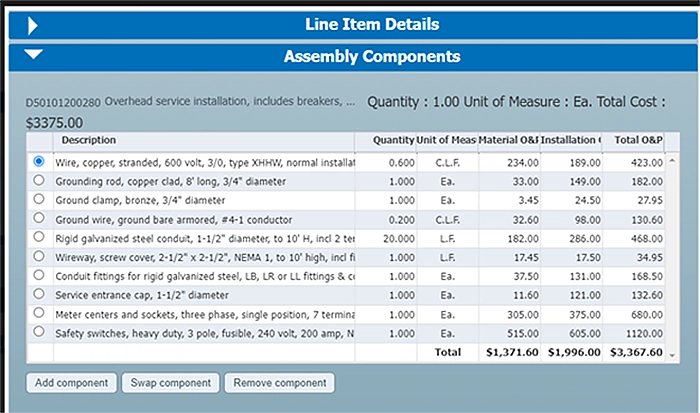

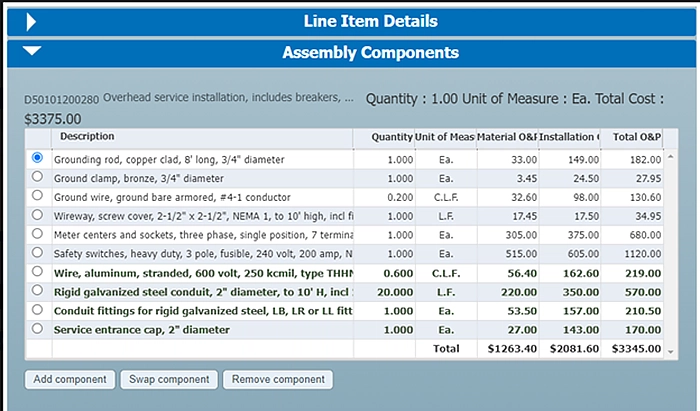

The example below uses RSMeans Data Online to compare a 200A service entrance. The first one uses copper cable 3/0 and a 1-1/2” conduit. The second one uses aluminum cable 250 MCM and 2” conduit. The aluminum option is slightly cheaper overall, even though the cost of the wire went down 48% from $423 to $219 and the raceway components went up in price by 23%.

Option 1: Copper Cable

Option 2: Aluminum Cable

RSMeans Data Online is a powerful tool that allows you to compare options and make data-driven value engineering decisions to better support your projects. Want to try this out for yourself with different estimates and location factors, or trend this over time with the Historical Cost Index? Follow the links below to learn more about how to use these tools for your estimates, or sign up for one of Gordian’s training sessions to get hands-on guidance.

- Already have an account? Use one of our Product Guides.

- Use the Historical Cost Index to move your estimates over time.

- Use the City Cost Index to localize your estimates.

- Sign up for in-depth RSMeans Training.