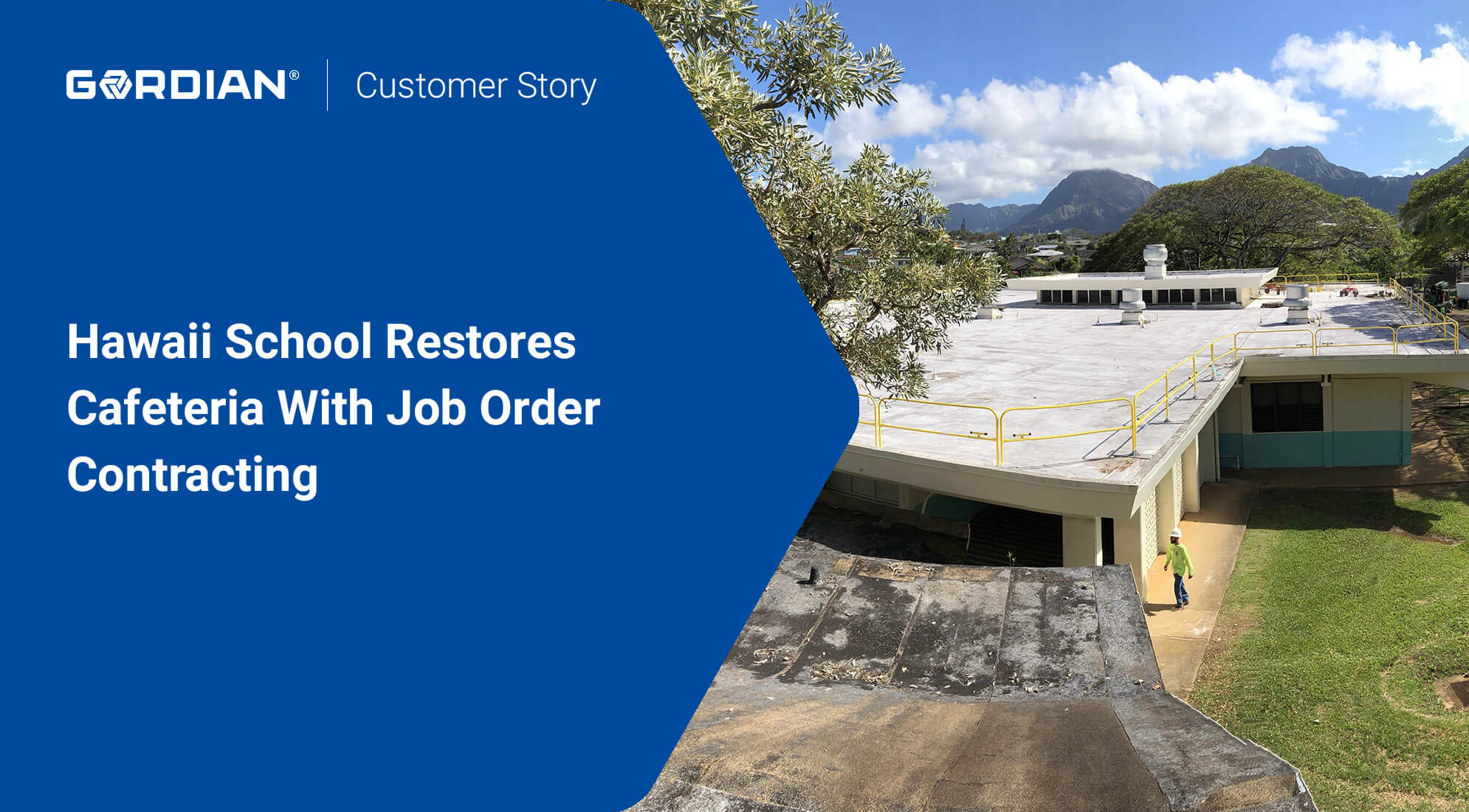

Gordian was founded by one of the creators of Job Order Contracting (JOC), and we’ve been perfecting the JOC process for over 30 years. But Job Order Contracting is only one of many methods for procuring construction services. Each one was designed for specific purposes and is best utilized for certain types of projects. Knowing the differences between them and when to use each delivery method can determine a projects’ success.

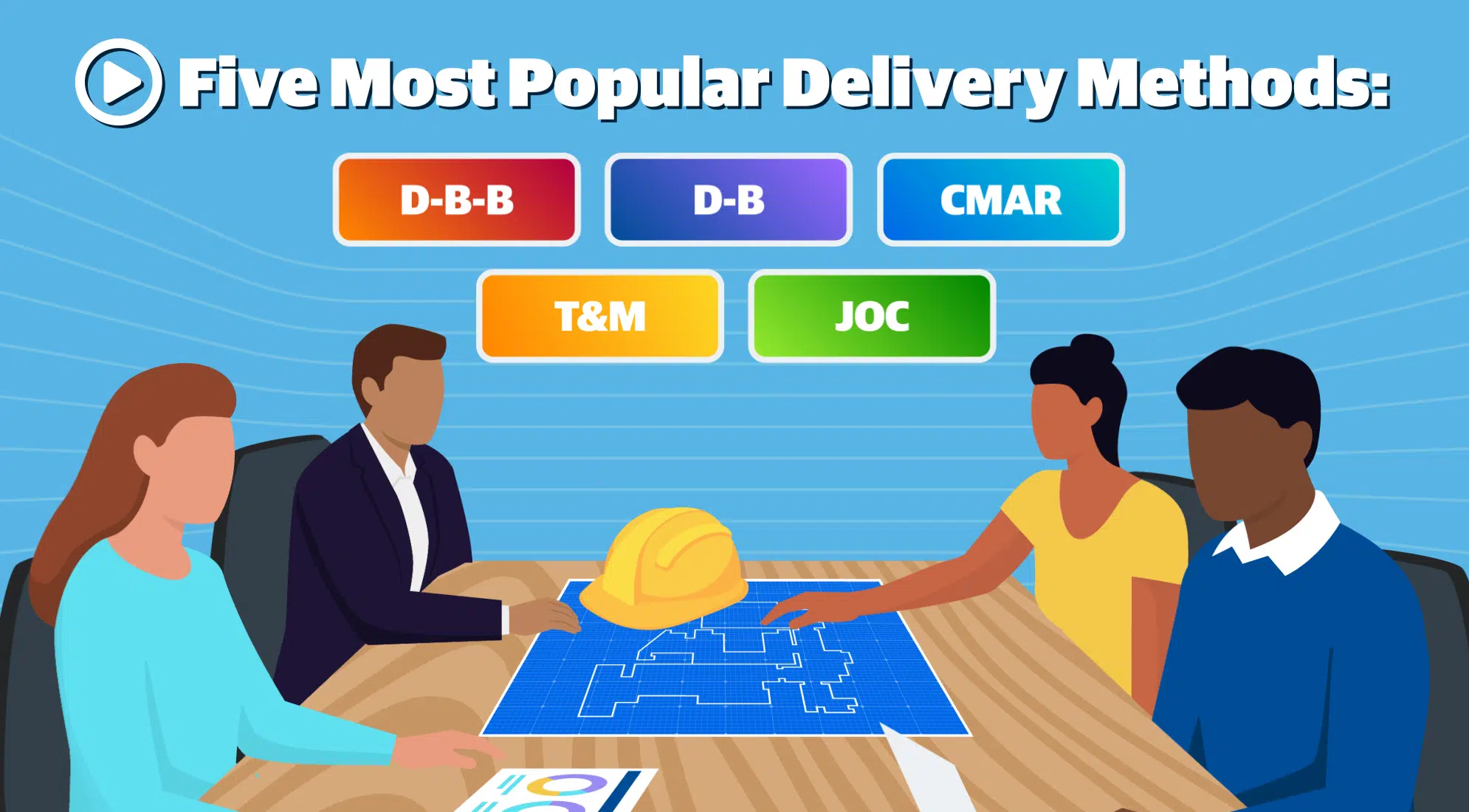

Let’s take a look at a few of the most widely used project delivery methods in the construction industry: Design-Bid-Build, Design-Build, Construction Manager at Risk, Job Order Contracting and Multiple Award Task Order Contract.

1. Design-Bid-Build (Traditional Building)

Design-Bid-Build is the most commonly used method for completing construction projects and is probably what comes to mind when most people think about the construction process. As its name suggests, this delivery method consists of three distinct phases: the design phase, the bid phase and the build phase. Design-Bid-Build is a good option for new commercial construction. Although it’s a lengthy process, it allows owners to work in tandem with architects and engineers to get the best price for their project.

The design phase begins with an owner hiring a designer, either an architect or an engineer, to design a new facility. While designing the new building, the architect or engineer will prepare any necessary drawings and specifications that the contractor’s team will need to complete the construction work. Once the design work is finished, the project is opened for bids.

During the bid phase, general contractors will review construction documents, confer with any needed subcontractors and ask the architect or engineer clarifying questions in order to prepare their bid. Each bid represents a general contractor’s best price for a project, and multiple bids for the same project can vary greatly. After all of the general contractors have submitted their respective bids, the designer will review each bid, ask the contractors for any additional information and, ultimately, choose the bid they think best fits the owner’s needs.

Once the winning bid has been selected, the build phase begins, and the general contractor’s team can get to work constructing the new facility. A unique feature of the Design-Bid-Build method is that the designer will oversee the work of the general contractor and subcontractors. This helps ensure that the owner receives a quality end product.

2. Design-Build (D-B)

The Design-Build method was created to reduce the lengthy timeline that often accompanies Design-Bid-Build. It does so by replacing the designer and the contractor with a single party who fills both of these roles, called a design-builder. The design-builder, who is usually an architect, engineer or contractor, serves as the owner’s single contact for the entirety of the project. And while this allows for efficient communication, it also means that the design-builder is singularly accountable for the outcome of the project.

The D-B process begins with an owner drafting an initial project design and asking for project proposals from various design-builders. These proposals, like bids in the Design-Bid-Build method, generally represent a design-builder’s best price for the project. The key difference between a bid and a proposal is that proposals include notes on the project design, whereas bids don’t alter the project design. Owners typically select the proposal that provides the best value for the project without sacrificing design elements.

After the owner has chosen a specific proposal, the design-builder’s team can get to work securing permits and beginning construction immediately. The project can also be completed in phases, where the first phase is designed and construction begins while the second phase is designed, again allowing for a faster start to construction. This makes Design-Build ideal for large projects that require an accelerated timeline.

But the benefits of D-B also add some risk to the owner. Owners who choose the D-B delivery method for their projects lose the advantage of having a separate party oversee the quality of construction. Instead, the design-builder has complete autonomy in the construction phase. So choosing a trustworthy design-builder is integral to success in Design-Build.

3. Construction Manager at Risk (CMAR)

Construction Manager at Risk, also called CM at Risk or simply CMAR, is also a derivative of the Design-Bid-Build process. But instead of the designer overseeing the design process and construction quality, a construction manager (CM) is hired by the owner to oversee the entire project. In fact, once hired, the CM stands in as the owner’s representative and advocate in every step of the construction process from preconstruction, to design and bidding, through construction. This makes CMAR ideal for project owners who want an expert’s help managing their project or communicating between parties, and sometimes CMAR allows owners to remove themselves from the majority of the construction process altogether.

When an owner decides to use the CMAR delivery method for their project, they’ll bring an initial design to a CM, who will then begin consulting with designers to draw up plans. During the design phase, the CM will work on the owner’s behalf to value engineer and find cost-saving opportunities where possible. About halfway through the design phase, the CM will present the owner with their Guaranteed Maximum Price (GMP). With their GMP, the CM sets a price threshold that they promise the owner’s project will not exceed. If the project comes in under this threshold, the CM will likely be rewarded by the owner through a cost-sharing agreement. But if the project exceeds the GMP, then the CM takes on the risk of making up the difference.

Once the design phase is finished, the CM will take bids from contractors for the project and select the bid they believe best meets the owner’s needs without crossing the GMP threshold. Once construction begins, the CM will work with the contractor to schedule construction phases, oversee the quality of the contractor’s work and coordinate any needed change orders.

4. Job Order Contracting (JOC)

Job Order Contracting is an indefinite-delivery, indefinite-quantity (IDIQ) project delivery method. This means that multiple projects can be completed over the life of one long-term contract, as opposed to the single-project contracts used in the three previous methods. The long-term contract makes JOC an ideal choice for owners who complete a high volume of construction projects over the course of each year. Rather than needing to take each project to bid, owners take bids from contractors at the beginning of the contract, then can access their services without having to re-bid throughout the entire life of the contract.

The JOC project delivery method is predicated on a catalog of construction Tasks with preset prices, which we call the Construction Task Catalog (CTC), that lives for the entirety of the contract. Having the CTC set at the beginning of the JOC contract allows owners to access contractor services at any point during the agreed timespan without having to renegotiate prices for each project. Rather than bidding on individual projects, contractors will place bids by adding an adjustment factor to the CTC to account for their overhead, profit and other operating costs. Owners will typically award the contract to the lowest responsive, responsible bidder.

Video Series – Job Order Contracting 101 – Watch this video series to learn more about Job Order Contracting (JOC) and Gordian’s Procurement Solutions.

After the contract is awarded, the winning contractor can perform work for the owner at any point needed. Each project will be preceded by a Joint Scope Meeting to make sure all parties agree on what work needs to be completed and to set a Detailed Scope of Work for the project. Once the scope is set, the contractor will submit a Price Proposal for the total project cost, the owner will review the Price Proposal and work will get started. Procurement for traditional projects can take six months or more. JOC cuts that down to a few weeks. That time savings also brings significant cost savings by reducing administrative work. And the preset pricing makes sure that cost overruns are minimized.

Because the JOC method is designed to complete a succession of pre-defined construction tasks, it’s perfect for a variety of small to medium construction projects including repairs, renovations and maintenance work, especially when short timelines or fixed budgets are involved. JOC, however, isn’t typically an ideal choice for new construction. Building a catalog of Pre-Priced Tasks for constructing an entire building would be burdensome, and the length of the project would negate the timesaving benefits of completing smaller projects in quick succession.

There’s a lot more we could say about JOC and why we think it’s an incredible innovation. If you’d like to hear more about JOC from us, you can find information here. But for now, we’ll move onto other project delivery methods.

5. Multiple Award Task Order Contract (MATOC)

Like Job Order Contracting, MATOC is an IDIQ method that’s commonly used by the military and the Federal government. It sets a long-standing contract under which multiple projects can be completed. MATOC is distinct, though, as it houses multiple contractors under a single master contract. While JOC doesn’t prohibit the use of multiple contractors under one JOC program, it doesn’t necessitate it. Because of this, the terms JOC and MATOC can be used interchangeably for certain projects.

The MATOC delivery method begins with a master contract, sometimes called an umbrella contract, which defines the parameters of work that can be completed under the program. The owner will select a pool of contractors they want to participate in bids for projects. When the owner is ready to start a project, they’ll take bids from only the contractors pre-selected to participate in the MATOC program. When a winner is selected for a project, a smaller, project-specific contract will be written between the owner and the contractor who will complete the project. Although a separate contract is written for each project, the details in the master contract reduce the number of details that need to be re-negotiated for the project contract.

The benefits of MATOC largely mirror those of JOC – reducing the procurement timeline and controlling costs. However, because MATOC is used most often by the Federal government, which generally prefers to set contracts with longer timeframes than just a year or two, it can be hard for smaller, local contractors to enter into MATOC contracts. In contrast, JOC, which is used in a variety of industries, normally encourages the participation of local contractors.

Each of these project delivery methods has its own merits and potential shortcomings. So being aware of their differences and respective advantages will help you better plan your next project. Even if you’ve only utilized one of the above methods before, it can be worth looking into others. Who knows, you could discover newfound savings in time, energy and costs.